INSIGHT: Vertical Integration in fuel and power generation industry

Convergen Energy takes non-recyclable industrial by-products, repurposes them into fuel pellets, and produces energy for the grid at its fuel plant in Wisconsin

Vertical integration for Libra’s renewable fuels and power generation, Convergen Energy, has become a daily reality since its acquisition of the L’Anse Warden Electric Company (LWEC) power plant in late 2016. The combined heat and power (CHP) 20-Megawatt facility located on the shore of Lake Superior in the Upper Peninsula of Michigan, for the first time allowed Convergen to produce its own energy from the fuel pellets it manufactures.

Ted Hansen, CEO at Convergen Energy, sets it out clearly: ‘Vertical integration is a huge step forward for us. In the past, we relied on fuel sales to customers. By changing the model with the purchase of our own power plant, we become vertically integrated, providing our business and customers with a continuous outlet for these materials which are otherwise destined for landfill.’ And a new end-customer was introduced with the generation of both steam and electricity for sale. LWEC supplies electric power to the grid for the Upper Peninsula under a power purchase agreement for renewable energy. The plant also supplies steam and electricity to a local business that is adjacent to it in L’Anse, MI.

The past two years have also seen an increased desire throughout sectors to reduce industrial by-products destined for landfill, driven by cost measures along with environmental concerns. ‘There didn’t used to be that much drive to get the materials out of the landfill, but we are finding more and more that our suppliers’ own customers are pushing them to be landfill-free and to demonstrate sustainability.’ Added benefits include certificates of destruction to show that material is not going to landfill, and verification that a brand display material or packaging is protected against counterfeiting or second-hand usage.

Working with recyclers and waste haulers, Convergen’s value-add proposition introduces a complete waste-to-energy, landfill-avoidance solution. ‘Every customer is different,’ adds Ted Hansen. ‘Some will do more to be landfill-free. Others understand that their landfill costs may decrease with the right volume and distance from our facility. Some want a more economical opportunity for their business. As an alternative energy company, we try to make it work for all of these parties in the most seamless way possible.’

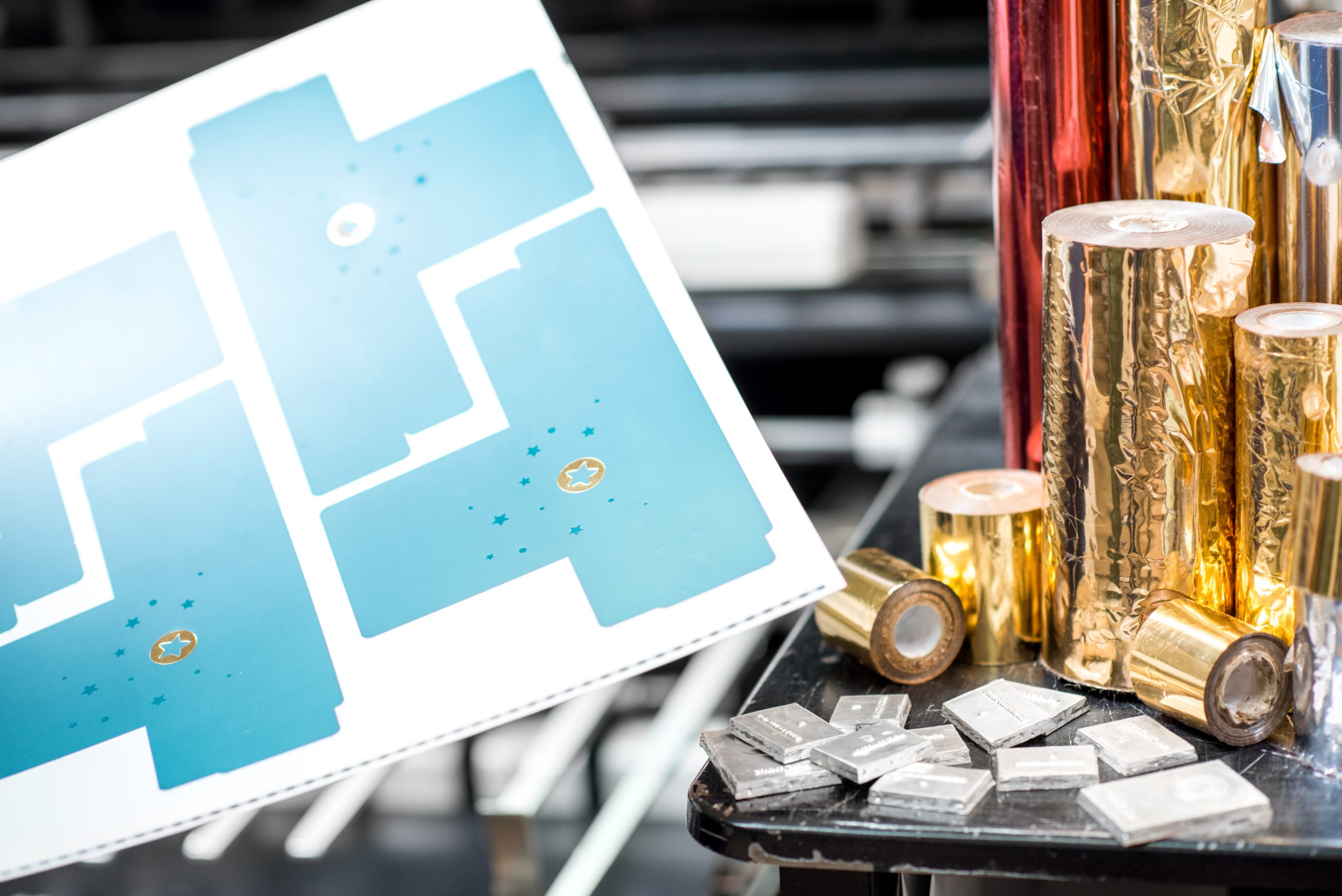

Recently, Convergen has been working with the Foil & Specialty Effects Association (FSEA) and its partnership with Channeled Resources Group which finds sustainable alternatives for non-recyclable waste and other obsolete materials. The upside is that it provides feedstocks for Convergen’s engineered fuel pellets and a sustainable solution for FSEA members at the same time.

These materials would have no value in secondary markets and would otherwise be sent to landfill. Suitable feedstocks for Convergen include spent hot and cold foil rolls. The stamping process results in a very attractive end product but more than 50% of the material used usually goes to a landfill. With rising disposal costs and increased landfill tipping fees, in some places over 25% in one year, the option of sustainable waste disposal at equal or lesser cost compared with landfill disposal is a win-win. This fits neatly into Convergen’s vertical integration chain and has seen its processing volume increase threefold since July 2017.

Taken together, this model sets a very positive course for the future of both power generation and waste disposal. In a world where greater consumption means a demand for more energy in addition to increased waste, that is welcome news.

To read more about Convergen Energy’s work in the field, see Liner recycling: dispelling the myths and Alternative Available for Hot and Cold Foil Waste.

Libra Interns at Concordia Americas Summit 2018

Libra Interns at Concordia Americas Summit 2018  LCI AW139 transitions across continents, customers and roles to land with Elitaliana

LCI AW139 transitions across continents, customers and roles to land with Elitaliana  The HOME Project announces grant from the IKEA Foundation

The HOME Project announces grant from the IKEA Foundation